OUR PRODUCTS

MADE IN GERMANY

ORELTECH’s unique metallization solutions come in two distinct product categories:

OTECH CONDUCTIVE INKS and OTECH COATING SOLUTIONS.

The choice of product depends on the application method: choose OTECH INKS for inkjet, aerosol jet, microdispensers, and other printing methods, or choose OTECH COATING SOLUTIONS for spray coating, slot die coating, dip dyeing, bath coating, rotating barrel and many others.

Currently available metals are silver, gold, platinum, and palladium. Other metals (e.g. iridium or copper) can be developed upon request.

All products are metalized by fast and simple plasma treatment. ORELTECH’s unique plasma curing process allows green, economical production without generating toxic waste. By using plasma, you can save up to 95% on electric energy!

To learn more about plasma curing, read our blog or contact us.

When you choose OTech products, you choose to optimize the use of precious metals in your product, lower your carbon footprint, and cut production costs.

OTech conductive inks have a unique, particle-free formulation that directly improves the printability of the inks without clogging printer nozzles. Our particle-free formulations are significantly more environmentally friendly than alternatives on the market. The resulting layers are high-performing regarding conductivity, flexibility, and stability and of the highest purity.

NEW: OTech Palladium CONDUCTIVE INK

OTech Palladium

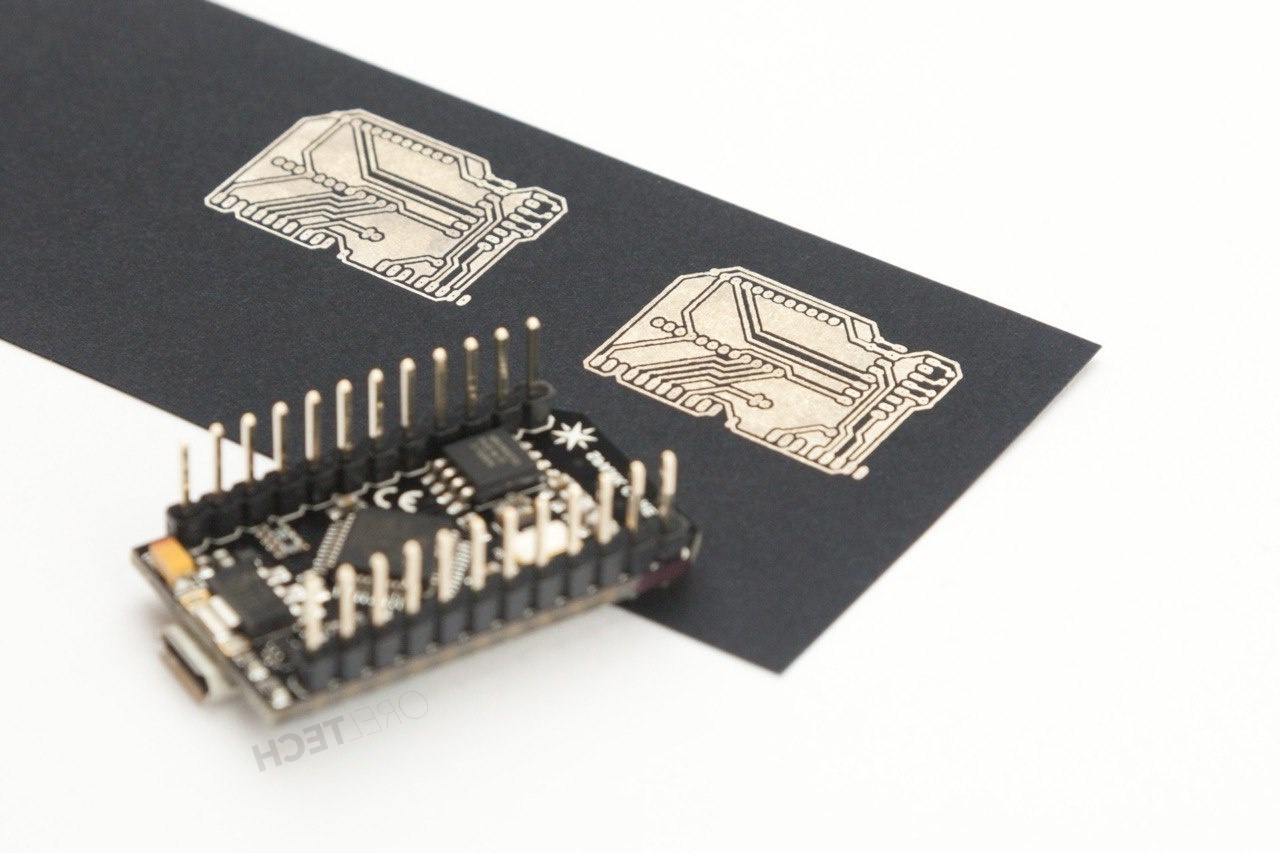

The world’s first printable palladium, ideal as seed layer for patterned PCB for subsequent plating, or for any other custom application.

PRODUCT DESCRIPTION

OTech Palladium is the world’s first commercially available printable palladium. Just like all OTech inks, it shows superior printing performance with various printing systems. The resulting palladium layers exhibit high conductivity, flexibility, stability, and durability.

APPLICATIONS

PCB seed layer, flexible electrodes, catalytic coatings

FEATURES

- Nanoparticle-free formulation

- No polymer binders

- Viscosity: 3-10 cP

- Curing process: cold plasma

- Curing temperature: <70°C

- Curing time: 5-10 min

- Compatible with Epson, Dimatix, Spectra, Konika Minolta, Ricoh, and other printheads

- Substrates: epoxy resins, PET, PI, ABS, fabrics

BENEFITS

- No nozzle clogging

- Material saving

- No solid or liquid waste

- Customizable formulation

LAYER PROPERTIES

- Flexible

- Durable

- Sheet resistance: 50 Ω/□

- Layer thickness: 20 - 100 nm

Minimum order quantity: 30 mL

OTech Aurum CONDUCTIVE INK

OTech Aurum

OTech Aurum plays its strengths where waste-free deposition, high-precision printing and high purity of gold layers are required. Compact gold layers are fully biocompatible, making them the preferred choice for medical-grade electrodes and coatings.

PRODUCT DESCRIPTION

OTech Aurum is made with medical devices and biosensors in mind. Gold layers prepared with OTech Aurum are non-toxic and biocompatible. After going through plasma curing, no organic traces are left within the layer.

APPLICATIONS

Flexible electrodes, printed medical sensors, biosensors, biochips, biowearables, medical grade coatings

FEATURES

- Nanoparticle-free formulation

- No polymer binders

- Viscosity: 3 - 20 cP

- pH: >2

- Curing process: cold plasma

- Curing temperature: <70°C

- Curing time: 10-15 min

- Compatible with acid-stable Dimatix, Konika Minolta, Ricoh, aerosol jet and microdispensing devices (Microdrop)

- Substrates: polymers (TPU, PET, PI, PEI, ABS, PC-ABS, PEEK), glass, paper, fabrics

BENEFITS

- No nozzle clogging

- Material saving

- No solid or liquid waste

- Low toxicity (no cyanides!)

- Customizable formulation

LAYER PROPERTIES

- Flexible

- High purity

- Biocompatible (comparable to ISO 10993)

- Sheet resistance: 0.5-3 Ω/□

- Layer thickness: 100 - 1000 nm

Minimum order quantity: 30 mL

OTech Platinum CONDUCTIVE INK

OTech Platinum

World’s first printable platinum, adequate both for high purity/medical grade layers and highly efficient catalytic systems.

PRODUCT DESCRIPTION

Platinum is a material of choice for applications that require mechanical and chemical stability or good performance. OTech Platinum conductive inks are formulated so as to address different functionalities that are sometimes required of platinum.

LIST OF OTech Platinum PRODUCTS

- OTECH PLATINUM OP711 - An ink that after curing with plasma reduces to nanosized Pt catalytic centers. This form of platinum is typically used in fuel cells, medical components, or DSSC solar cells.

- OTECH PLATINUM LA731 - This ink reduces to a high surface area Pt catalytic structure after curing with plasma. These structures have an application in fuel cells and batteries.

- OTECH PLATINUM TF721 - The formulation of this ink allows metallization into a full-coverage platinum layer. This type of ink can find an application as a coating for medical components or even decorative purposes.

APPLICATIONS

Catalysis, medical-grade electrodes, sensors and biosensors, neuroelectronics, corrosion protection, and fuel cells

FEATURES

- Nanoparticle-free formulation

- No polymer binders

- Viscosity: 3 - 20 cP

- pH: >2

- Curing process: cold plasma

- Curing temperature: <70°C

- Curing time: 10-20 min

- Compatible with acid-stable Dimatix, Konika Minolta, Ricoh, aerosol jet (IDS) and microdispensing devices (Microdrop)

- Substrates: polymers (PET, PI, PEN), glass, paper, fabrics, inorganic particles

BENEFITS

- No nozzle clogging

- Material saving

- No solid or liquid waste

- Low toxicity

- Customizable formulation

LAYER PROPERTIES

- Flexible

- High purity

- Biocompatible (comparable to ISO 10993)

- Sheet resistance: 5-10 Ω/□

- Layer thickness: 30 - 1000 nm

Minimum order quantity: 30 mL

OTech Silver CONDUCTIVE INK

OTech Silver

Our product line of OTech silver conductive inks covers a wide range of applications. Each OTech silver ink is optimized for different functionalities or deposition methods.

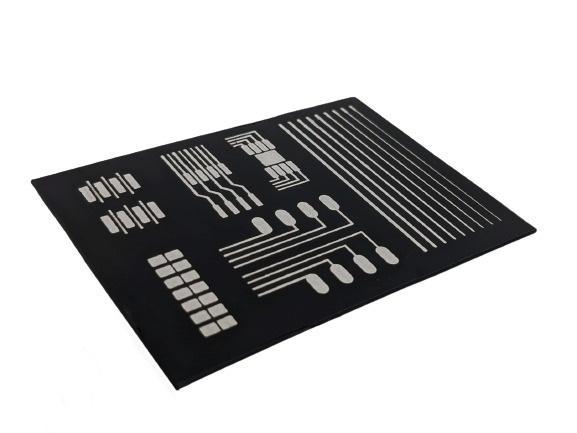

PRODUCT DESCRIPTION

The OTech Silver family of inks includes an inkjet optimized ink for high-performance silver layers, an ink for transparent layers, and an ink for direct printing on fabrics. All products are free of solid content, non-toxic, low waste, and their processing consumes only a fraction of the energy of most alternatives on the market.

LIST OF OTech Silver PRODUCTS

- OTECH T - Specialized for printing of conductive layers with more than 80% transparency. Ideal for flexible transparent electronics. Data Sheet

- OTECH JET - Optimized for inkjet printing. Enables printing of highly conductive, smooth and uniform layers and patterns. Data Sheet

- OTECH FABRIC - Optimized for printing on various textiles. Stays on-surface. Perfect for wearable electrodes and innovations with e-textiles. Data Sheet

APPLICATIONS

PCBs, flexible electrodes, OLEDs, capacitive sensors, chips on paper, EMI shielding, wearables, transparent conductors, ITO replacement, …

FEATURES

- Nanoparticle-free formulation

- No polymer binders

- Curing process: cold plasma

- Curing temperature: <70°C

- Curing time: 1-5 min

- Compatible with many industrial-grade print heads like Epson, Dimatix, Spectra, Konika Minolta, Ricoh, and other printheads, as well as aerosol jet (e.g. IDS) microdispensing devices (e.g. Microdrop)

- Substrates: polymers (PET, PI, PEN, PC, PEI, ABS, PC-ABS), glass, paper, fabrics

BENEFITS

- No nozzle clogging

- Material saving

- No solid or liquid waste

- Long shelf life in ambient conditions

- Customizable formulation

- Compatible with most industry print heads

LAYER PROPERTIES

- Flexible

- High purity

- Conductive

- Antimicrobial

Minimum order quantity: 100 mL

| METAL | CURING TEMPERATURE [°C] |

CURING TIME [min] |

VISCOSITY [cP] |

SHEET RESISTANCE [Ω/□] |

THICKNESS [nm] |

APPLICATION | |

|---|---|---|---|---|---|---|---|

| OTech T | Ag | <70 | 1 – 5 | 10 – 20 | ≤ 50 | 30 – 50 | For transparent layers (T up to 85%) |

| OTech Jet | Ag | <70 | 1 – 5 | 10 – 20 | 0.1 – 3 | 200 – 1500 | For high performance silver layers |

| OTech Fabric | Ag | <70 | 1 – 5 | 10 – 20 | 0.5 – 3 | 100 – 700 | For printing on fabrics and textiles |

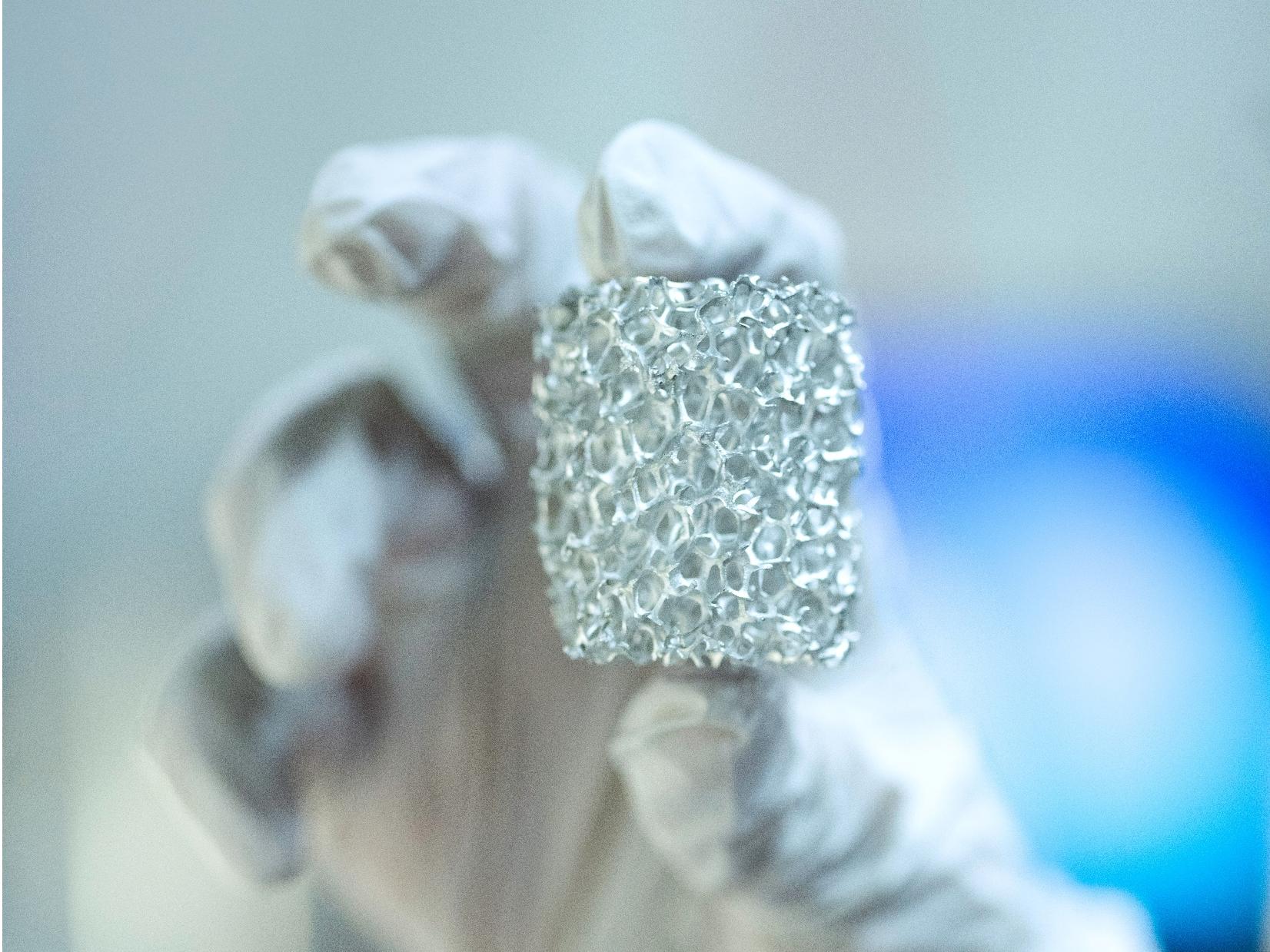

NEW: OTECH COATING SOLUTIONS

We introduce you to our new line of products, OTech Coating Solutions: A line of products optimized for the deposition of metal coatings. Low curing temperature makes our products particularly useful for coating temperature-sensitive materials like plastics. Electroplating experts praise ORELTECH technology as particularly easy and simplified process suitable for the coating of small plastic parts in small and medium quantities.

OTech Coating Solutions can be deposited with aerosol spraying, slot die, dip dye coating, and other coating techniques. Read more about the use of OTech Coating Solutions in plating on plastics.

New solutions for functional metal coatings

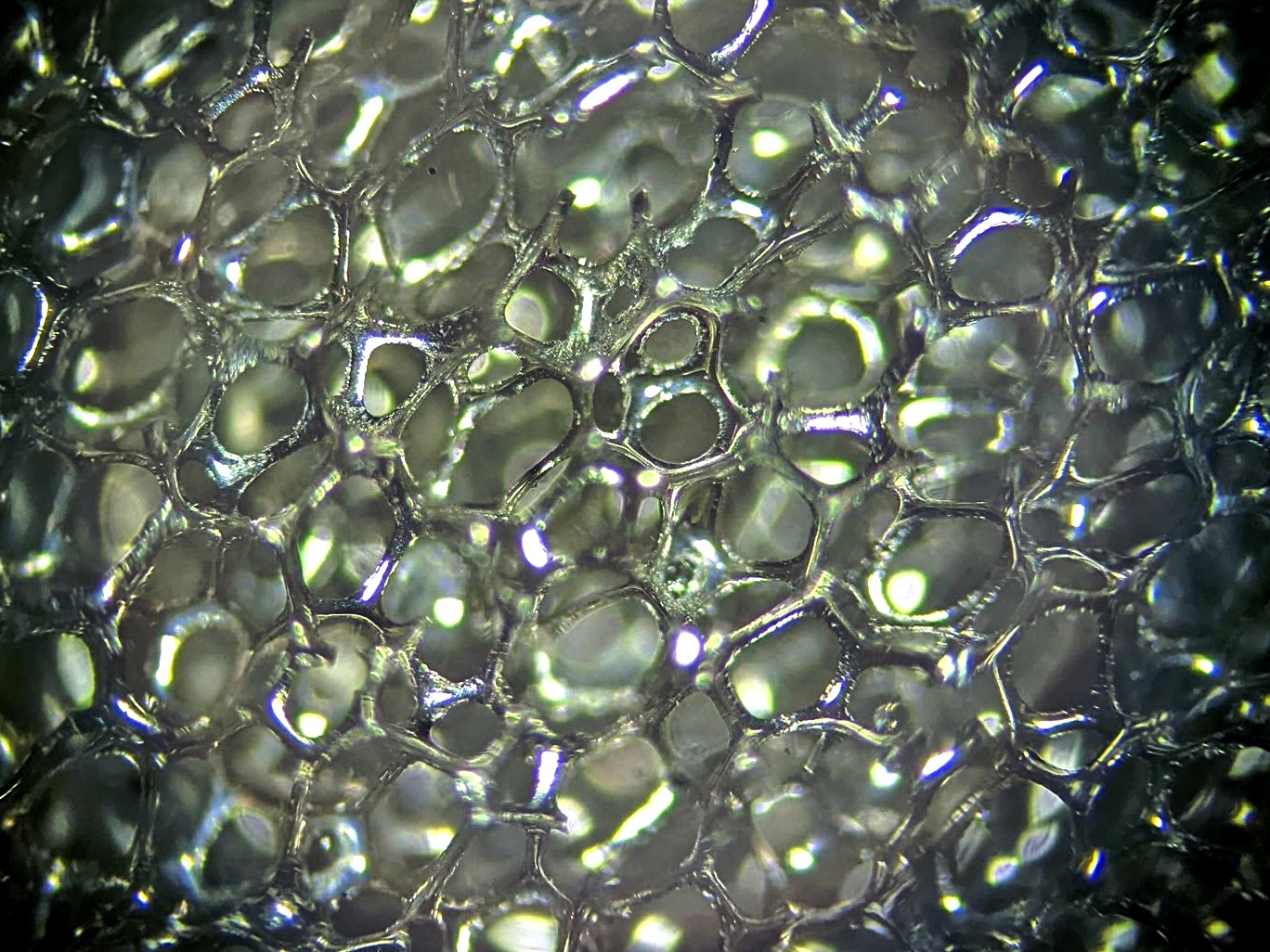

ORELTECH technology opens up new possibilities in coating deposition and processing with energy-efficient plasma curing and unique formulation that permeates into complex structures and ensures better performance with less material used.

Better coverage with less material

Because of their liquid formulation, OTech Coating Solutions can permeate complex structures and are therefore suited for the deposition of active metal layers such as antibacterial silver on filters or catalytic platinum on powders.

Whatever the supporting substrate, OTech Coating Solutions provide an even coverage of complex structures like foams, meshes or powders at a minimal metal consumption.

Electroless deposition on plastics

Plasma treatment of OTech Coatings enables direct deposition of metals on plastic surfaces. The process does not rely on electrochemical baths, seed layers or chemical treatments for successful coverage of plastic surfaces.

OTech Silver Coating Solution

Silver is broadly utilized as a coating for its antibacterial, anti-corrosive, electrical, and many other properties. It is a material of choice when it comes to precious metals as it provides the best trade-off between functionality and price.

Order now Data Sheet Ask a questionAPPLICATIONS

Antibacterial foams and meshes, antibacterial coatings, catalytic coatings, coating of plastics, protective coatings, metallized micropowders

FEATURES

- Curing process: cold plasma

- Curing temperature: <70°C

- Curing time: 3 - 5 min

- Layer thickness: 5 - 1500 nm

- Substrates: PEI, ABS, PC-ABS, PEEK, epoxy resins

BENEFITS

- Conductivity

- Material saving

- Low toxicity

- Customizable formulation

- Direct deposition onto the (non-conductive) surface

Minimum order quantity: 500 mL

OTech Platinum Coating Solution

Platinum coatings are used when a stable and functionally reliable material is needed. With its unique surface properties, platinum is most often used in catalytic or medical applications due to its biocompatibility. Because of its rarity, bulk metal is rarely used, and is replaced whenever possible with thin platinum coatings on less precious substrates.

Order now Data Sheet Ask a questionAPPLICATIONS

Catalytic coatings, coating of plastics, protective coatings, medical grade coatings, metalized micropowders

FEATURES

- Curing process: cold plasma

- Curing temperature: <70°C

- Curing time: 3 - 5 min

- Layer thickness: 5 - 1500 nm

- Substrates: PEI, ABS, PC-ABS, PEEK,epoxy resins

BENEFITS

- Catalytically active coating

- Material saving

- Low toxicity

- Customizable formulation

- Direct deposition onto the (non-conductive) surface

- Biocompatible (comparable to ISO 10993)

Minimum order quantity: 50 mL

CUSTOMIZED FORMULATIONS

Beyond our standard products, we have in-depth technical know-how and an extensive library of formulations to tailor the optimal liquid to meet the requirements of your unique metallization challenge. Contact us now to discuss your case!

Order nowPartner with us to bring your product to the next level