Introducing ARM

Create metal layers as simply

Create metal layers as simply

as using an airbrush

Metallize almost any substrate, at room conditions, in an instant.

All this without generating chemical waste or requiring high CapEx equipment.

What is ARM?

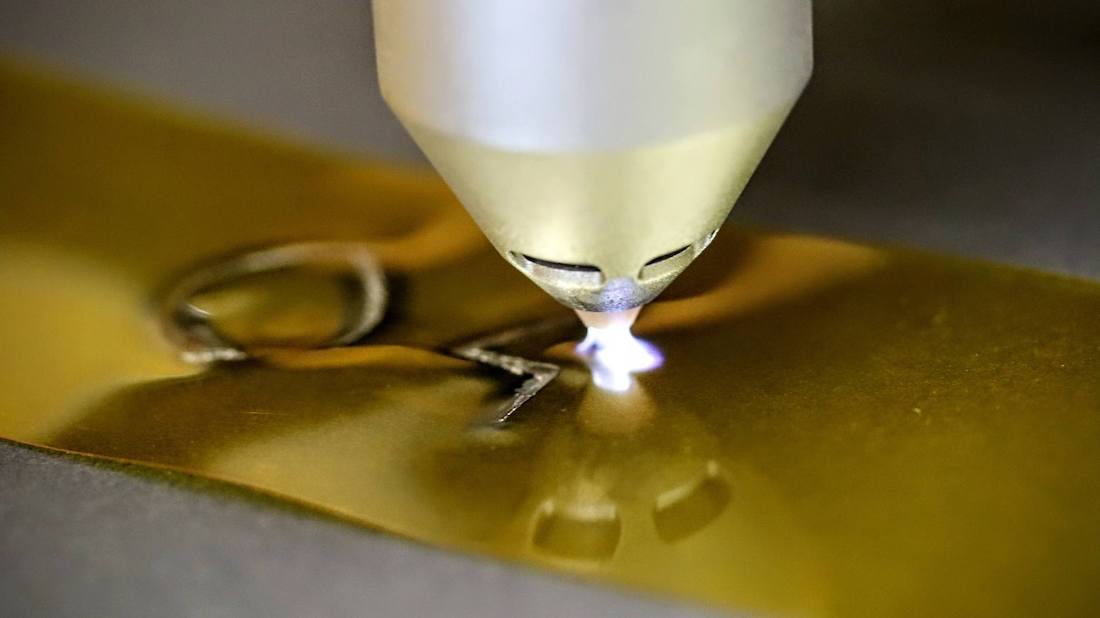

ARM stands for Ambient Rapid Metallization, a new metallization process developed by the scientists at OrelTech. A fusion between an aerosol jet printer and localized plasma jet technology, this one of a kind technology allows you to easily deposit and cure a wide range precious metals (Ag, Au, Pt and Pd) onto virtually any surface, all in room conditions, instantly.

Better yet, no additional post-treatment is required.

Coating and metalizing technologies abound.

What makes ARM different?

-

Coating of complex substrates made easy

Since ARM works much like conventional aerosol deposition, it excels on complex surfaces such as ridges and steps.

Even meshes and membranes can be done in a single pass.

-

Leave the vacuum for space, metalize at room conditions

ARM doesn't require any extraneous set up. With an ARM powered table-top system and OrelTech inks you're ready to go.

No vacuum, no clean room.

-

Coating at breakneck speeds

ARM creates metal layers in seconds. The unique combination of OrelTech's ATMOS inks makes this happen.

-

Control where you deposit and avoid material waste

OrelTech ARM system is composed of a nozzle that combines localized plasma jet and aerosol stream moves much like an airbrush. This gives you choose where to deposit material on the substrate and how much.

How does ARM work?

The core of ARM lies in OrelTech’s plasma-based metallization process and operates on three simultaneous processes:

-

1

Metal containing precursors are decomposed by the plasma and reduced to a pure metallic state. Instantaneously.

-

2

Accompanying solvents are also decomposed and evacuated with the working gas flow.

-

3

Pure metal entities, due to their high concentration, assemble into crystalline structures, forming polycrystalline networks and films that bond to the substrate via physisorption or metal bonding.

-

1

Metal containing precursors are decomposed by the plasma and reduced to a pure metallic state. Instantaneously.

-

2

Accompanying solvents are also decomposed and evacuated with the working gas flow.

-

3

Pure metal entities, due to their high concentration, assemble into crystalline structures, forming polycrystalline networks and films that bond to the substrate via physisorption or metal bonding.

How is ARM changing industries?

OrelTech's cutting-edge atmospheric plasma machine is rewriting the rules of industry and innovation. By harnessing the power of atmospheric plasma, we've unlocked a world of possibilities previously considered unattainable.

Talk to us

To achieve flawless integration, we collaborate closely with our customers from first feasibility tests to fine-tuning mass production. In this way, our customers benefit from customized solution with added value and efficiency from process to product while lowering your environmental impact.

Curious to learn more? Drop us a message in the contact form below and schedule a 1-on-1 meeting to talk to our experts.

OrelTech GmbH

Rudower Chaussee 29

12489 Berlin

Germany