ORELTECH

SOLUTIONS FOR FUNCTIONAL METAL COATINGS

Next-Generation Metal Coating for Modern Manufacturing

OrelTech's breakthrough metal coating technology redefines what's possible in surface coating and metal plating.

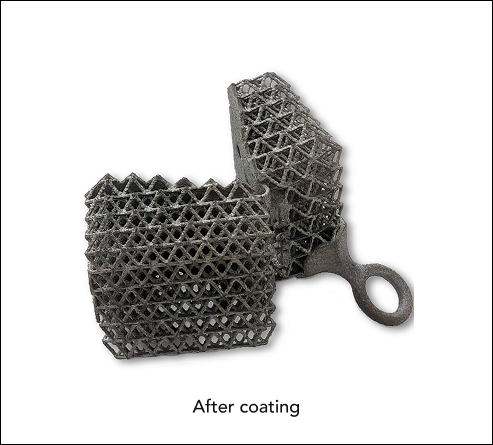

By combining advanced chemistry with low-temperature processing, we enable high-performance metal coatings on even the most challenging substrates — from precision injection-molded plastics to complex 3D-printed components.

Superior Seed Layers for Plating on Plastic

Traditional plating on plastic often struggles with poor adhesion, high metal costs, and toxic chemicals.

OrelTech changes that.

Our patented process creates a pure metal seed layer directly on polymer components - no etching baths, no organic residues, no toxic waste. This ultra-thin conductive layer forms the ideal foundation for electroplating, delivering stronger adhesion, lower metal usage, and flawless coverage even on intricate designs.

Together with Biconex, specialists in sustainable electroplating, we take this seed layer to the next level - adding thick, high-quality copper or nickel finishes. The result is a durable, high-precision metallic surface coating with unmatched appearance and performance, perfectly suited for functional and decorative applications alike.

Why Choose OrelTech

Whether for injection-molded or 3D-printed components, OrelTech’s surface coating technology delivers:

Ultra-thin, pure metal

seed layers

Silver, Palladium, Gold,

and Platinum available

Flawless surface

finish

Low-temperature

processing

Exceptional

adhesion

Environmentally friendly

and cost-efficient

Learn more about our coating technology

Explore how OrelTech’s innovative metal plating and coating solutions can enhance your products.

Contact us to discuss your application or request a quotation.

OrelTech GmbH

Rudower Chaussee 29

12489 Berlin

Germany