Platinum’s role in the green energy transition cannot be understated. Its unique chemical composition allows platinum to be both highly catalytic, facilitating chemical reactions without being consumed by that process. As well as being very resistant to corrosion and oxidation, ensuring the longevity of components in harsh environments. These properties have made it a shining star in this growing industry, with multiple applications in hydrogen electrolyzers and fuel cells alone, plus many more in other technologies.

It’s a sought-after resource, but unfortunately a rare one to find in nature, keeping its price and availability at a premium. When manufacturers in these green industries consider how best to apply this precious resource, there are two metallization methods that immediately come to mind: Vapor Deposition (VD) and Plating (chemical and electro). A third one, perhaps less obvious, is OrelTech's Plasma Metallization. In this article we’ll explore the relative benefits and drawbacks of each of these methods.

Comparing contemporary methods.

Vapor Deposition (VD) is a well-established process known for its precision in controlling layer thickness, making it a reliable choice for industries that demand exacting standards.VD is achieved by heating a material to a vapor phase and then condensing it onto a substrate, forming a thin film or coating. It typically takes place within a vacuum chamber to eliminate contaminants and control the deposition environment, ensuring precise thickness and purity of the deposited material. VD consistently delivers pure metal layers that meet stringent quality criteria, further enhancing its appeal across various applications such as the coating of silicon wafers, or optical coatings.

A notable limitation of VD is its line-of-sight requirement, limiting its applicability in complex geometric configurations. The necessity for a high-vacuum environment makes adaptation to continuous roll-to-roll (R2R) production a formidable task. Lastly, patterning during VD typically demands the use of masks, a step that can result in the significant loss of later subtracted material, which adds to the overall cost of production, especially when working with precious materials like platinum.

Plating; another well established method of depositing platinum is plating which offers remarkable versatility, capable of operating across a broad temperature spectrum. Plating is achieved by immersing the substrate in a solution containing ions of the desired plating metal. Electrons are applied to the object electrically or chemically causing the metal ions to be reduced and deposited onto the substrate's surface, creating a thin, uniform layer. It is a well-established and easily scalable process, widely adopted in diverse industries such as the manufacturing of PCBs as well as jewelry. Furthermore, its compatibility with various substrates makes it a versatile choice for numerous applications.

While offering some advantages, plating presents a specific set of challenges. One significant concern is its generation of substantial chemical waste. With increased environmental considerations in its application, leading to limitations and bans across a number of countries, for example chrome plating in the EU in 2024. Moreover, plating's inherent batch-oriented nature makes it less adaptable to continuous roll-to-roll (R2R) production processes. Additionally, like with VD, the requirement for masks in the patterning phase can result in material waste, underlining the need for careful materials management in plating operations.

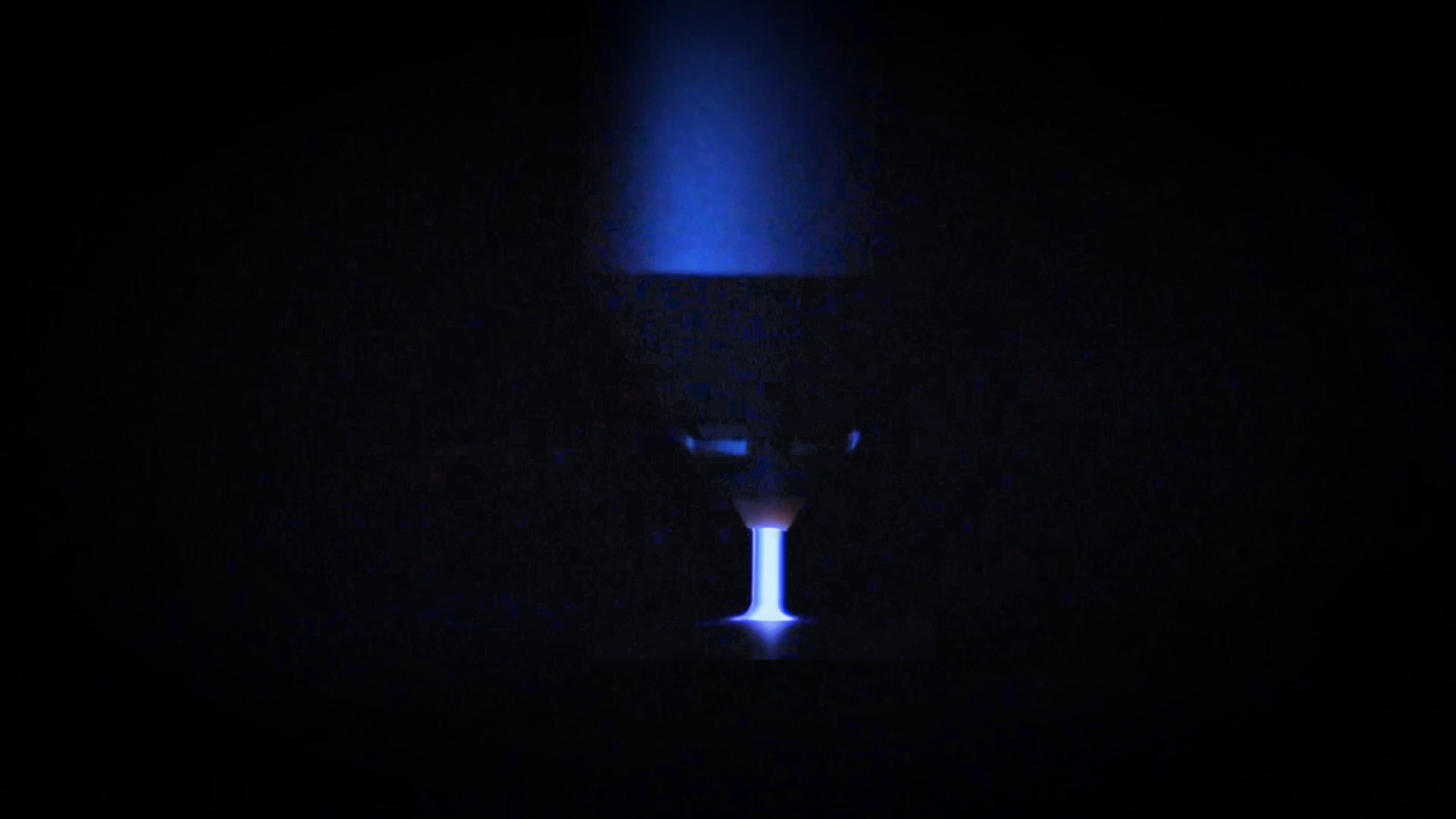

A third and innovative method is based on metallic inks. OrelTech's Metallization process stands out for its precision in controlling thickness and maintaining exceptional metal purity. It distinguishes itself by operating at ambient temperatures during deposition, resulting in energy efficiency. This sustainable approach includes generating zero chemical waste, making it environmentally friendly. Furthermore, the method is readily scalable for various industrial applications and simplifies patterning through efficient printing techniques. The latest development in this method has also recently arisen with the addition of platinum to the portfolio of available inks, making it shine as the only method available on the market for platinum printing.

The OrelTech metallization process, while offering numerous advantages, has some limitations to consider. It is primarily suited for creating thin layers, typically up to 1.5 microns thick. Additionally, the requirement for a plasma chamber, though a piece of equipment widely available in many sizes, can pose challenges to those who do not yet own one. Lastly, it is a relatively new method in comparison to more established techniques like VD and plating.

Platinum deposition, are innovations around the corner?

With green technologies like clean hydrogen production seeing wider adoption and continuous innovation, cornerstone materials like platinum will continue to play crucial roles in their developments. This precious metal, though unique in its properties, poses challenges simply due to its scarce nature, thus the choice of deposition method is a key consideration for manufacturers looking to create cost effective products. In the world of modern industry, platinum deposition is quickly becoming a cornerstone process, enabling the utilization of this precious metal in critical applications like fuel cells, batteries and sensors. While Vapor Deposition and Plating are widely established methods, OrelTech's Plasma Metallization is emerging as a real alternative, offering highly controllable deposition resulting in significant material savings, and ease of integration into various manufacturing processes including R2R. To continuously expand and enhance these advantages, OrelTech is working hard every day to make pure metal deposition as easy as drawing with a pen. Stay tuned.