A quick guide to Printed Electronics

Consider a modern smartphone manufacturing facility. Chances are, in your mind’s eye you are seeing a huge hangar filled with plastic-covered tables, attended to by plastic-covered people, who painstakingly assemble a never-ending array of devices by hand. Chances are they are also exhausted and underpaid for that high-precision, high-focus job. This mental image alone should be reason enough to change our approach.

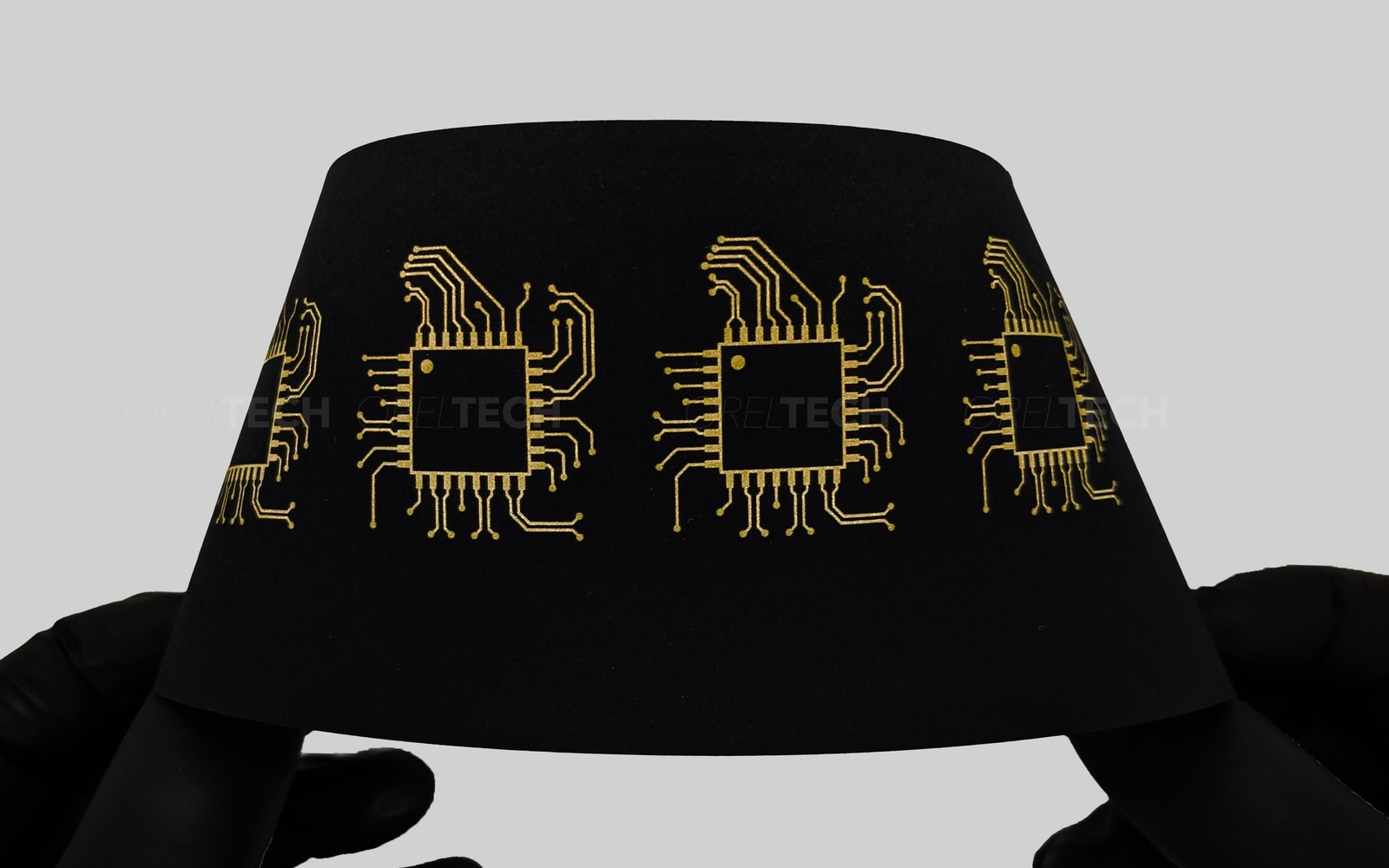

Image source: Venture Outsource

Of course, the demand is king here. We wouldn’t need these hangars, if not for a growing need for more and more electronic devices. We need new stuff - or, at least, we want new stuff, and the market is happy to oblige. The same thing happens with a lot of other commodities - washing machines, microwave ovens, even cars are needed by millions, but at least with larger devices, the robots can do the job. Alas, they are not yet precise enough for smartphones.

In addition, we, as consumers, always want the products to be cheaper. That is such an ugly word - cheaper, ugh! - so in presentations and advertisements euphemisms like “cost-efficient” or “affordable” are often used, but it is all the same to us. We just want to pay less money for better products, and this need is creating stress on the market. Which, in turn, creates stress on plastic-covered people in hangars.

It doesn’t take an economist to see that this situation is not sustainable in the long term - people don’t grow on trees. So the electronics industry is already looking into alternative approaches to smartphone assembly. Something that can guarantee you a faster and cheaper high-precision production. And immediately, the printing process comes to mind. Instead of putting together the smartphone piece-by-piece, imagine rolls upon rolls of smartphones, rushing through the huge printers, smelling of wet paint and electrical components. This seems to be the optimal future for device production.

So why are we not already doing this, you might ask. Where is the bottleneck? After all, we know we can print plastics fairly well. There are technological roadblocks there too, of course, but many solutions are available. But plastic-only electronics is still not market-ready, despite all the wonderful advances of the field in recent decades. You still need metals for conductivity, and they are obviously hard to print.

Luckily, there are solutions to that as well - a whole range of them. Metal 3D printing is a big thing right now, but it reaches printability through high temperatures, which is hard to combine with plastics. A brilliant idea is nanoparticles - metal in the form of tiny particles that are held back from sticking together by chemical “separators”. From that, you can make so-called conductive inks. They can be quite liquid, enough to be printable. Once printed, you just have to remove the “separators”, and then you are left with a metallic layer. Unfortunately, this removal is also usually done at high temperatures - not the “molten metal”-high, but surely the “destroy plastics”-high.

Fortunately for the smartphone industry, brilliant ideas do not stop there, and the next one is - particle-free ink. Metals can exist in the form of ionic materials, i.e. salts, just like sodium metal exists in table salt, for example. These can be dissolved in liquids and used this way, just like salt can be consumed when dissolved in soup. The trick then is to turn them back to metals after they are printed, and more so, to do it without high temperatures or dangerous chemicals. Currently, only one technology is capable of doing exactly that in a safe, green and simple way - plasma metallization, a process which is developed and patented by OrelTech.

Is our future paved with printed smartphones? Possibly. More and more devices are being printed, and more and more manufacturing processes switch from assembly hangars to printing houses. It starts, of course, with simpler devices - chemical sensors, strain gauges, antennae, capsenses, touchscreens. The next step are fully printed OLEDs for lighting and displays, solar cells, and more complex medical devices.

But eventually, I believe, we will print smartphones as well. Why? Because we can.

Dr. Konstantin Livanov