Conductive inks can be prepared with a range of different materials, namely metal nanoparticles, conductive polymers, carbon materials, and organic/metallic compounds. Most commercially available conductive inks today are based on metal nanoparticles.

At OrelTech, we have developed a completely new type of conductive ink which is based on a metal ionic solution. In short, OrelTech's inks are nanoparticle-free.

But what does it mean? Why is the absence of nanoparticles so important and does it really offer an advantage over “classical” nanoparticle inks? Well, as you will shortly learn, the absence of nanoparticles offers several important advantages:

1. No nanoparticle synthesis

In our production process, there is no need to synthesize nanoparticles because we don’t use them. This is a big deal. There are many downsides to the use of nanoparticles. Nanoparticle synthesis is expensive, low-yield, time-consuming, energy-consuming, and produces a lot of chemical waste.

At OrelTech, we skip this step altogether, and just with that, we already save a lot of time and resources.

2. Plasma curing

Our curing process is also novel (and proprietary). Instead of heat or UV, we use cold plasma curing. But don’t let the fancy name scare you away! Plasma metallization is a quick and simple process. It occurs at low temperatures - always below 70°C - and does not produce any liquid or solid waste. You can say that it is by far the greenest metallization process available today.

Plasma instruments are a staple in many industries and manufacturing processes and the use of them is quite simple. We talk about plasma options in a little bit more detail here.

3. Thinner printed layers

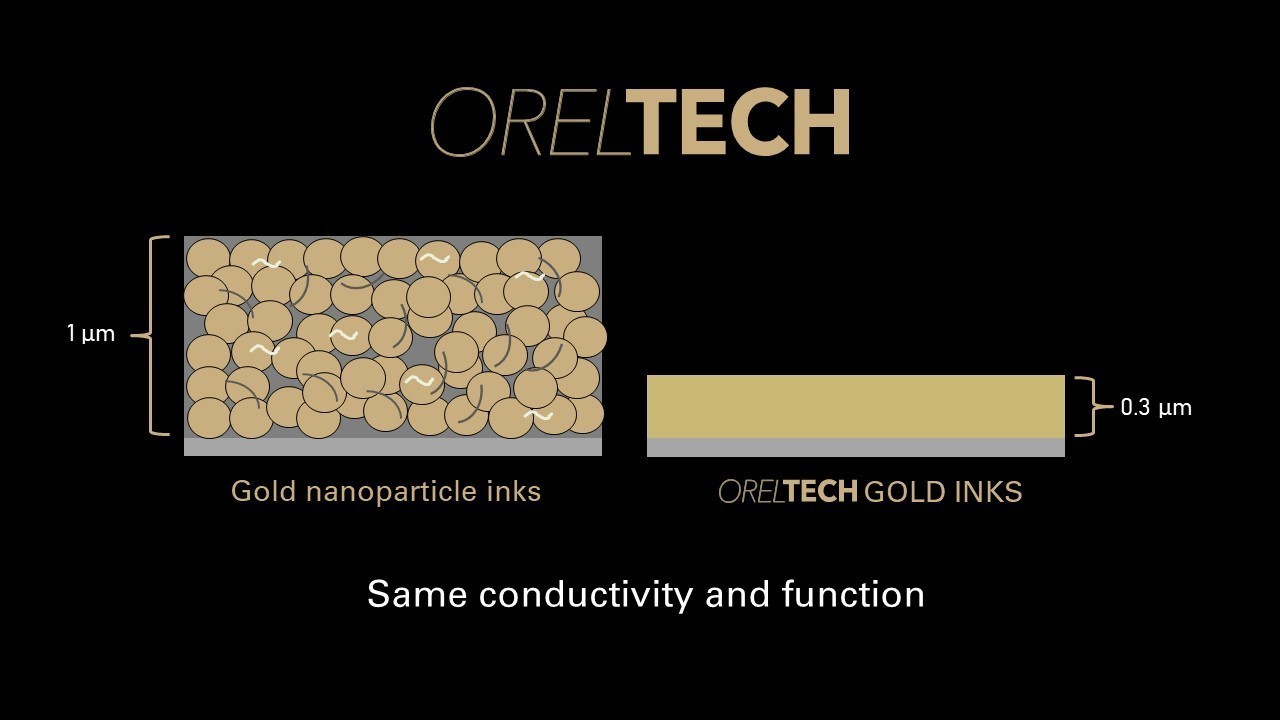

Ultimately, the thickness of the printed layer will depend on the base material. That means that the layers created with nanoparticle inks will be limited by the size of nanoparticles.

Since OrelTech’s inks are based on ionic solutions, we are able to produce much thinner layers. The density of the film created with our inks is higher, so we need a lower metal thickness to achieve the same conductivity as a nanoparticle film. This is the reason why we can proudly offer silver transparent conductive inks.

4. Better resolution of printed patterns

An additional benefit related to the printing process is the lack of limitations on feature dimensions. No nanoparticles means that your line width is not limited by either particle size or ink viscosity, but only by your printer capabilities.

5. Better adhesion to the surface

Another consequence of using ionic instead of nanoparticle solution is that our inks can achieve much better adhesion to the surface.

Think about the difference between snow and ice. The established approach - nanoparticle inks - behave like snow. Nanoparticles are deposited on top of the surface and then connected together. In our approach, metal behaves like ice: it grows directly on the surface (see the scheme below). That means better adhesion, but also better cohesion, higher stability, density, and lower roughness.

6. Substrate compatibility

We have a large ink library with inks suitable for many different substrates, ranging from glass to paper, and from common polymers like PET or Kapton to fabrics. We can find a good fit for your substrate, and if not, we can make a new adjusted ink. We have extensive R&D experience in suiting inks to the, let's say, tricky materials.

7. No clogging of the printer nozzle

A well-known technical issue of inkjet printing with conductive inks is that nanoparticles tend to aggregate around the printer head nozzle which leads to clogging and poor printing performance. No nanoparticles - no clogging.

8. The overall price of an electronic device manufacturing

Considering all of the reasons stated above, and the fact that the price of electrode manufacture can make up to 80% of device price, it is obvious that OrelTech’s technology can introduce a significant cost-reduction to the manufacturing process of printed electronics. Even if it happens that you need to invest in a plasma machine, the long-term cost savings that our technology enables far outweighs that initial cost.

Dr. Kristina Lovrek

This article was originally published on LinkedIn on October 21, 2020. https://www.linkedin.com/pulse/8-reasons-switch-nanoparticle-free-metallization-inks-kristina-lovrek/